BIOBASED CHEMICALS

Different options for circular aromatics

Achieving fully circular aromatic chemistry remains challenging, with little likelihood that a single technology will become as universally applicable as petroleum distillation. However, multiple approaches show promise.

The mass balance approach could give access to BTX in a circular manner. However the value chain of chemical recycling still has to be developed and scaled up to unlock its full potential. Lignin-derived aromatics, currently at pilot scale, are likely to remain focused on highvalue fine chemical applications due to the complexity of the products generated during lignin depolymerisation.

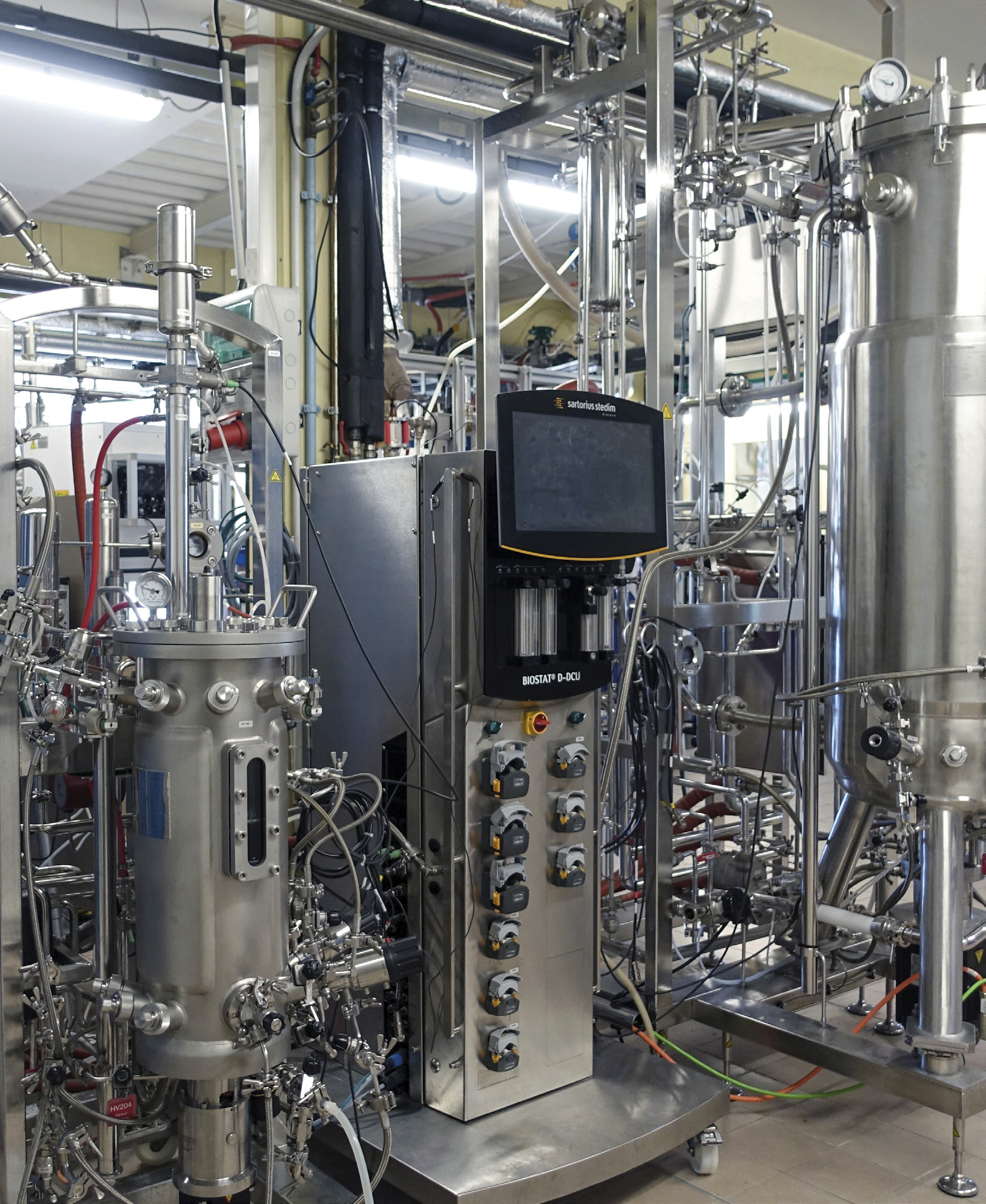

Meanwhile, fermentation has proven its reliability in producing substituted aromatics derived from aminobenzoic acids. These compounds are now available at tonne-scale, paving the way for the development of a comprehensive catalogue of biobased aromatic chemicals tailored for speciality chemical applications. ●

In addition to biobased AA, Pili has also developed a second compound at industrial-scale: paraaminobenzoic acid (PABA, 4-amino benzoic acid, CAS: 150-13-0, Figure 2). PABA serves as a versatile precursor for a range of applications, including pharmaceuticals, sun care ingredients, and the production of dyes and pigments. The first 250 kg batch has been produced at 97% purity, and part of this output will be used internally to manufacture highperformance pigments,

The product is now commercially available and REACH-registered in the 10-100 tonnes/year range.

Wider possibilities

AA is a key raw material in the production of several pigments but is also a fragrance precursor. Initial batches have already been converted into biobased indigo and Pili is now exploring additional markets. AA is just one or two chemical steps away from aniline, benzoic acids or phenols, enabling a broad catalogue of biobased aromatics in the future.

The company has entered a new fundraising round in order to build its first production unit to meet the growing demand of biobased dyes and pigments, in particular indigo. While the price of biobased aromatics remains slightly higher than their conventional counterparts, economies of scale should significantly narrow the price gap within the next decade.

In 2024, Covestro announced a pilot programme using a similar technology to produce biobased aniline. The company seeks to replace one of its key raw materials in polyurethane manufacturing with fermentation-derived biobased aniline, with support from the German government. As yet, Pili is not aware of the outcome.

Guillaume Boissonnat-Wu

MANAGING DIRECTOR PILI guillaume@pili.bio www.pili.bio J j52 SPECIALITY CHEMICALS MAGAZINE ESTABLISHED 1981