SUSTAINABILITY

requirements by means of protein engineering, instead of the process being tailored to the catalyst.

Conclusion

Biocatalysts are nature’s toolbox enabling sustainable synthesis with a high stereo- and regioselectivity and the opportunity to tune them for a distinct reaction. In a well-optimised biocatalytic process, one kg of biocatalyst enables the formation of one tonne of product at yields of >95% and ee of >99%.

Biocatalysis is a proven and industrially validated alternative to chemical synthesis over two decades and keeps growing, mainly driven by the motivation to access new chemical modalities and establish more sustainable and ‘natural’ synthesis routes. For both newcomers to the field of biocatalysis or experienced users, numerous partners like Aminoverse providing support, services and products to facilitate entry or help expanding the footprint of biocatalysis. ●

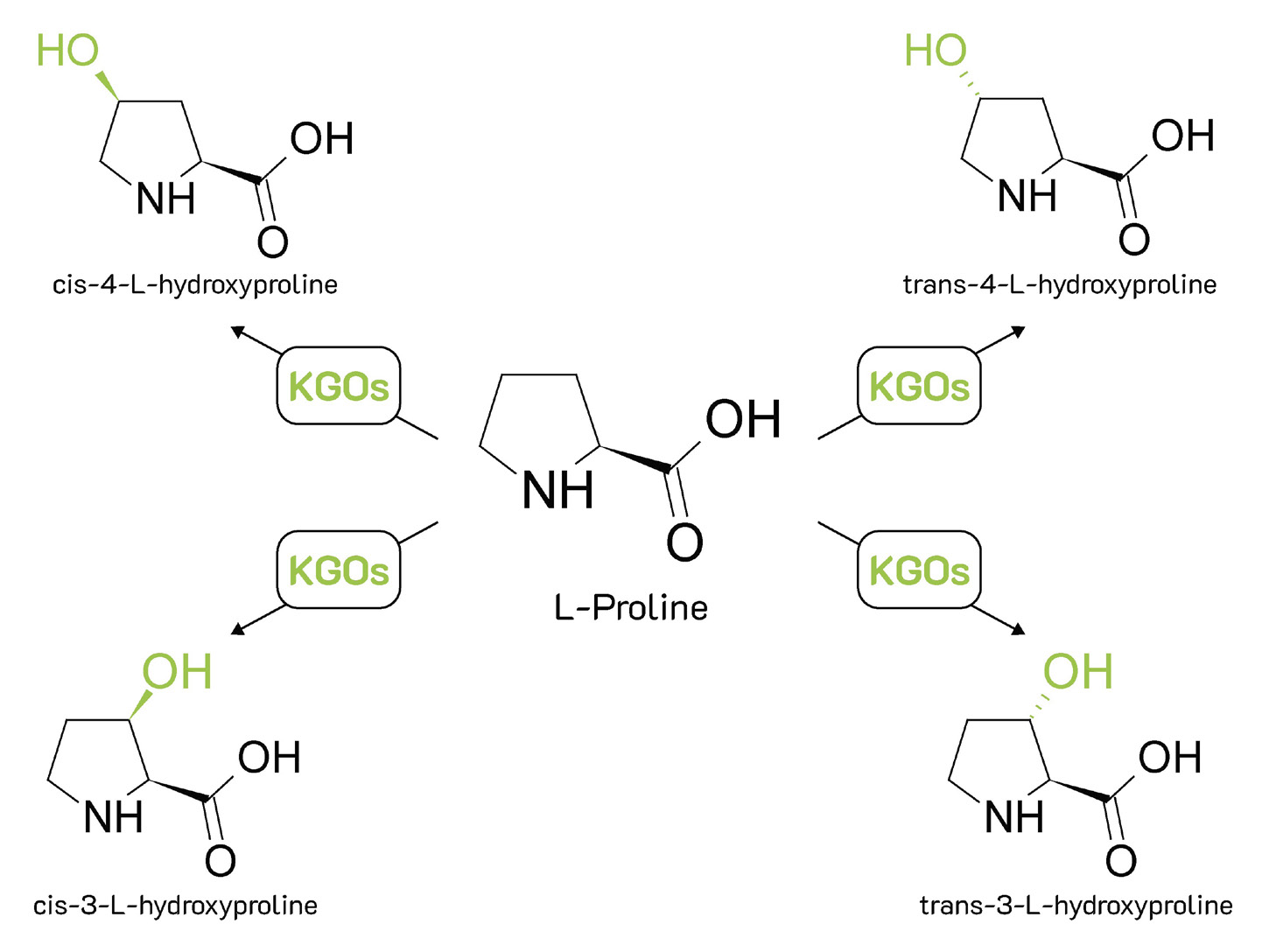

Figure 4 - Modification of the amino acid L-proline with KGOs to API precursors Note: Adapted from Hara et. al.Lipases, the most commonly used biocatalysts, are available for ~$10/ kg thanks to production capacity at the high tonnes scale, while UPOs currently cost around $10,000/kg. However, there are several strategies to significantly reduce the cost contribution of biocatalysts.

Chemical patents usually protect molecules and synthesis routes. If only the synthesis route is protected by IP, or for generics, biocatalysis should be an integral part of synthesis route scouting, especially since the resulting routes are typically shorter with higher yields and thus more cost-efficient.

If a biocatalyst is subject to patent protection, it may be replaced with a different biocatalyst capable of performing the very same reaction. Service providers like Aminoverse support finding the replacement for a biocatalyst or modifying it for unrestricted use.

References: 1: C. M. Heckmann et al., ACS Catalysis, 2024, 14, 2985 –2991. 2: R. Hara et al., Applied Microbiology and Biotechnology, 2019, 103, 5689 –5698.Immobilisation allows biocatalyst recycling and recovery thus typically reducing biocatalyst cost of goods sold (COGS) five- to ten-fold. If paired with (semi)-continuous manufacturing in flow, the COGS can be reduced ten- to 100-fold.

The times when the production of a target biocatalyst took months are definitely over. Nowadays, most biocatalysts with industrial relevance are available off-the-shelf. Where is no commercial source for a desired biocatalyst, it can be made available within a few weeks. Generally, the supply of biocatalysts can quickly scale from milligrams to kilograms or even tonnes and allows unhindered scale-up of the process.

In addition, depending on the product margin, one should aim for certain substrate-to-biocatalyst ratios to ensure economic viability of the process. These range from 25:1 for high-margin compounds (e.g. pharmaceuticals) to 100:1 for medium-value compounds (e.g. cosmetics) and 500:1 or higher for bulky, low-cost chemicals. Where these ratios cannot be achieved, the biocatalyst can be improved by means of protein engineering.

The development time for a biocatalytic process is often seen as the biggest hurdle. As initial solution the supply of ready-to-use biocatalyst kits can minimise the research time to find a suitable biocatalyst within one or two weeks. Beyond that, the greatest advantage of biocatalysts compared to inorganic catalysts is the fact that they can be tailored towards the process

David Schönauer

CEO & FOUNDER AMINOVERSE BV k +31 452 084815 J schoenauer@aminoverse.com j www.aminoverse.comMAR /APR 2025 SPECCHEMONLINE.COM

61